Page updated / checked 2.1.2025.

Order penetration point is the point in the material flow where a product becomes earmarked for a specific customer: for example in make-to-stock production OPP is located in the finished goods inventory. The products are produced with internal production orders into the finished goods inventory, and they are delivered based on customer order from the finished goods inventory to the customer.

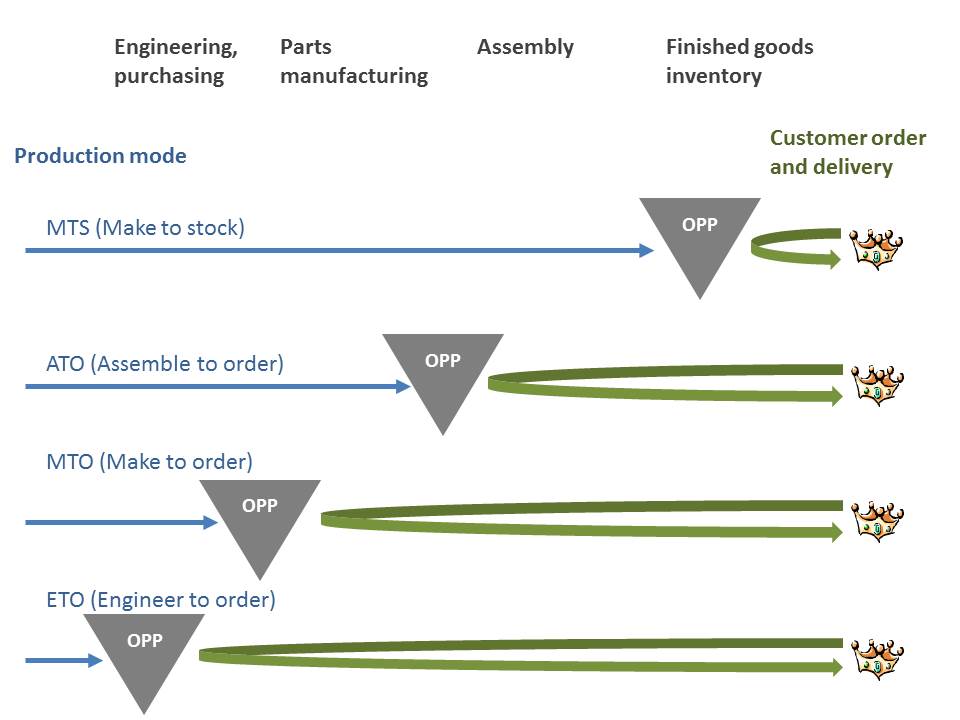

The picture below shows the most typical OPP locations and the corresponding production types: MTS (make to stock), ATO (Assemble to order), MTO (Make to order) and ETO (Engineer to order). In addition to these basic types, other types can be defined through the location of OPP, when it is defined more precisely what actions take place triggered by customer order, and what actions prior to the customer order. Also the term (order) decoupling point is used for OPP.

The location of Order penetration point has an impact to the production itself, production planning and control as well as other operations in the organization. OPP impacts the delivery time to the customer: the closer to the customer the OPP is (to the right in the picture above), the shorter the delivery time for a customer order is. The customer gets his/her products faster from the finished goods inventory of a make-to-stock production, than from the production in make-to-order mode. All activities that happen after the OPP are part of the delivery time for the customer. Before the OPP the production is anonymous: production activities are carried out according to plans and forecasts with no direct link to the customer order. On one hand this implies more uncertainty in the production, but on the other hand it offers better possibilities to level the production for more efficiency. Usually there is a buffer inventory at the OPP location.

What is a good location for the Order penetration point? There is not a single one right answer to that question. Very short delivery time requirements from the customer usually lead to OPP close to the customer: if the typical delivery time for a consumer product is one day, making it to order is not necessarily possible. Large amount of variants and low predictability of future demand would imply an Order penetration point further away from the customer (i.e. upstream): it may be financially unfeasible to hold finished goods inventories in such a situation. High volume consumer products would be more likely to be in make-to-stock mode, while customer-specific industrial equipment would likely be engineered to order.

Companies typically have several different locations for Order penetration point depending on the demand for the product, amount of variants, possibilities for holding inventories and the criticality of short delivery time. The different OPP locations are visible to sales and customers in practice through different delivery classes.

Example

Equipment manufacturer sells its products in three different delivery classes. The high volume runner products have been modularized, which makes it possible to assemble these standard products to order. Delivery time is typically two weeks: when the customer order arrives, the product is assembled from standard modules which are available in buffer stocks, it is tested, packed and sent to the customer. In order to get this short delivery time the product has to consist of limited amount of pre-defined modules and no special materials are allowed. There is also a maximum order size: even if the order would consist of standard modules, it will be made to order if the order amount exceeds the agreed limits for this delivery class. The module amounts kept in buffer reflect these maximum order sizes.

Products made to order have longer delivery time, approximately one month. In the example company all products that are made to order have already been designed, the drawings and work instructions exist, and there are no special long lead time materials in the products. The third delivery class in the company is engineer-to-order: products which require product engineering for example a new feature in the product or a new application area. In these cases the delivery time is agreed case by case.